Ikat Art is a curated online atelier dedicated to authentic handwoven ikat — silk fabrics born in Uzbekistan, delivered worldwide.

Led by Mumtoz, a native of Uzbekistan, our small team works directly with master weavers, textile artisans, and centuries-old workshops. No middlemen. No mass production.

Our promise is simple: true craftsmanship, honest materials, and attentive care — from loom to your doorstep.

Explore our stories to discover ikat’s heritage, meet our artisans, and learn why this textile tradition matters.

Ikat Art: Where the Past Meets Silk

Central Asia has woven silk for four thousand years. Long before the Silk Road had a name, caravans carried these luminous fabrics from Samarkand to Baghdad, from Bukhara to Venice.

The technique known as khan-atlas — cloud silk — remains unchanged. Patterns are drawn not on fabric, but on threads themselves, before dyeing. The result: those distinctive blurred edges that have enchanted collectors for millennia.

At Ikat Art, we walk in the footsteps of those ancient traders. Our artisans still unwind cocoons by hand. Still dye threads in copper vats with pomegranate and indigo. Still weave on wooden looms passed down through generations.

This is not nostalgia. This is living heritage — and we invite you to become part of its story.

Artisans from around the world collaborate with our workshop. Our fabrics reach homes in Paris, New York, Tokyo, and beyond.

Our workshop in Uzbekistan carries its own rich history. Founded in 1972, it has nurtured generations of silk masters — weavers, dyers, pattern-makers — who dedicate their lives to a single craft.

Here, beneath hand-carved wooden beams, artisans produce adras, atlas, bekasab, and pure silk ikat. Every meter of fabric passes through dozens of hands before it reaches you.

From Cocoon to Thread: The Birth of Silk

It begins with silence — and boiling water.

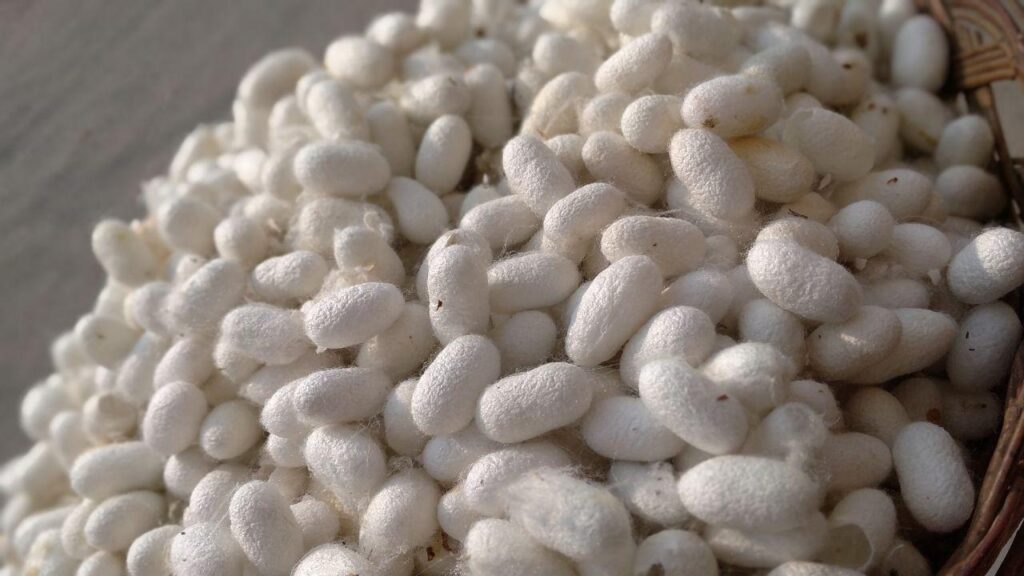

In our cocoon workshop, artisans gently submerge silkworm cocoons in traditional copper pots. The hot water softens the sericin, releasing threads so fine that a single cocoon can yield up to 1,600 meters of continuous silk fiber.

These cocoons weigh almost nothing — between 0.3 and 1 gram each. Yet within this weightlessness lies extraordinary strength. It takes 16 to 30 cocoons to form a single kalava — the cylindrical silk structure that becomes thread.

We waste nothing. Every fiber is unwound, cleaned, and prepared for the long journey to becoming ikat.

The Art of Thread: Preparation for Ikat

Raw silk is beautiful but unruly. Before it can become ikat, it must be tamed.

Our thread department transforms silk through a series of careful steps: winding, layering, steaming, and extraction. Each stage refines the fiber — adjusting thickness, enhancing sheen, ensuring durability.

We work with multiple silk types: raw, bleached, dyed, and blended. Depending on the desired texture, threads can be folded into 2 to 90 layers. This layering is what gives our fabrics their distinctive depth and drape.

Only when the thread is ready — perfectly wound, perfectly tensioned — does it move to the next stage: the creation of pattern.

Silkworm cocoons • Bound threads ready for dyeing • Fire heating the dye vats • Colored silk hanks after dyeing

The word “abrband” comes from Persian: abr (cloud) and band (to tie). Globally, this resist-dyeing technique is known as ikat. In Central Asia, we call it abrbandchilik — the craft of cloud-tying.

The magic happens before weaving begins. Artisans draw intricate patterns directly onto stretched silk threads. They then bind specific sections with wax-resistant ties, so those areas resist the dye. One color at a time, the pattern emerges — clouds forming in thread.

Creating ikat begins with a vision — drawn by hand onto silk threads themselves.

Before any dye touches the fiber, master artisans stretch hundreds of parallel threads across a long wooden frame. Using only chalk and intuition, they sketch the pattern that will emerge after weaving — calculating precisely which sections must be bound to resist each color.

This is the moment where mathematics meets art. A single miscalculation, and the pattern blurs. But when done with mastery, those characteristic “cloud edges” appear — the signature of true ikat.

Master craftsman drawing patterns • Measuring thread bundles for precise pattern alignment

The creation of abrband ikat demands both precision and patience. Patterns must be applied to silk threads before dyeing — a technique that allows for infinite variety.

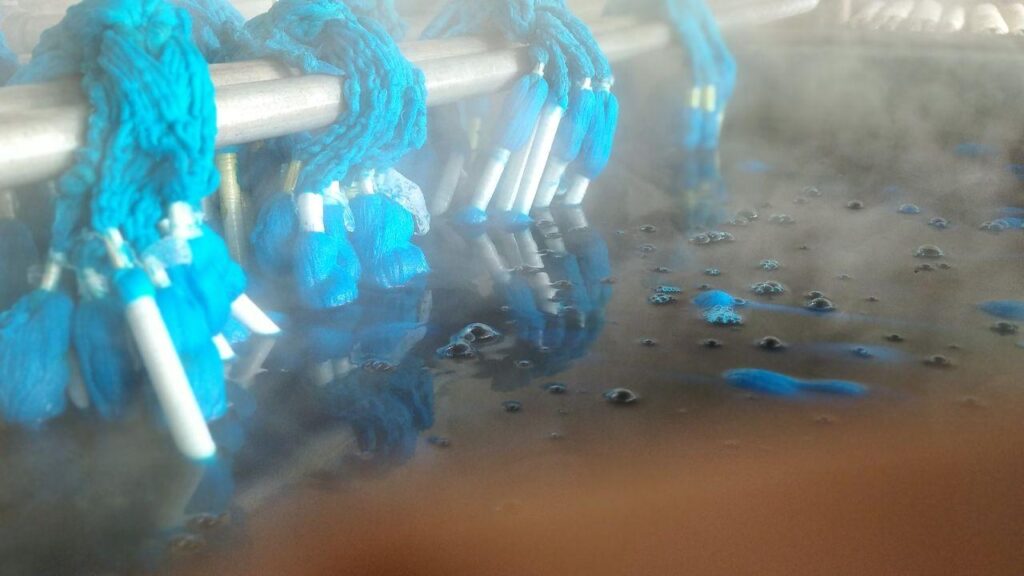

After binding, threads enter the dye vats — sometimes five, six, seven times for complex patterns. Each immersion adds a new layer of color. The process can take weeks for designs featuring 16 or more hues.

Our dyeing methods blend tradition with modernity. While we use natural dyes — indigo, pomegranate, walnut, madder — where possible, we also employ colorfast modern pigments when durability demands it. The result: ikat that maintains its vibrancy through years of use.

In our workshop: cloudy satin, cloudy direction, bekasab, atlas — fabrics ranging from 20 to 400 meters per run.

The ikat dyeing process is remarkably versatile. Depending on the desired pattern, silk can undergo various dyeing sequences — each creating unique effects and color harmonies.

In the realm of abrband, tradition dances with innovation. Master weavers draw from classical motifs passed down for centuries, yet seamlessly incorporate contemporary elements. The range of colors in our patterns — from subtle two-tone compositions to complex 16-color symphonies — showcases the depth of this textile art form.

The making of abrband ikat is an art that balances precision with intuition.

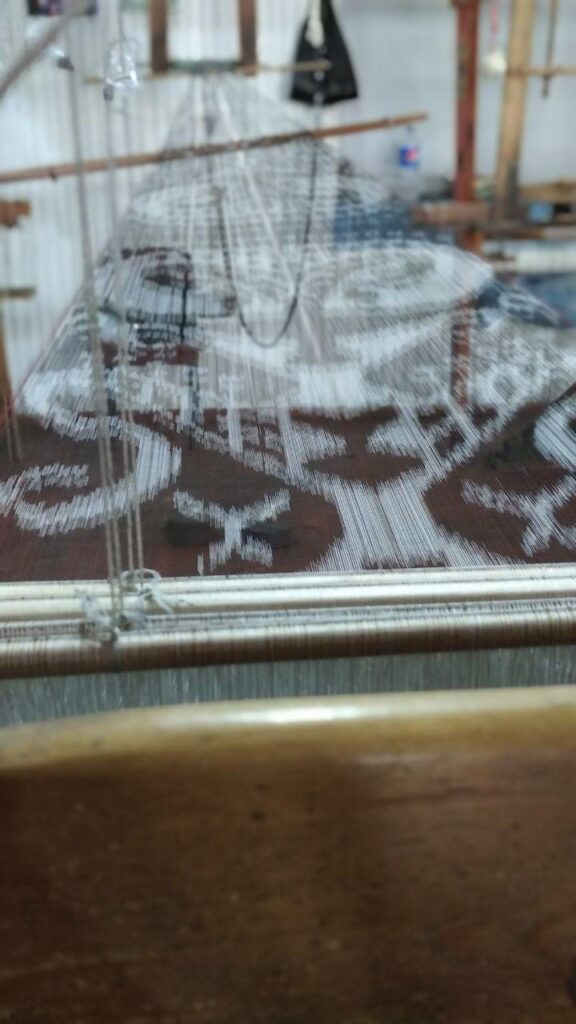

Once threads are patterned, bound, and dyed, they arrive at the loom — where months of preparation finally become fabric. The weaver’s task is deceptively simple: align each thread so the pre-dyed pattern emerges correctly.

But this “simple” alignment requires decades of experience. A single thread out of place, and the pattern distorts. Our master weavers adjust by touch, by instinct — correcting the natural shifts that make each piece unique. This is why machine-made ikat can never replicate the soul of handwoven cloth.