How are ikat made and what is it?

I want to talk a little about natural fabrics, which even in our fast-paced times, some craftsmen still weave by hand from cotton and silk, and also hand-dye, and often even with natural dyes – indigo, madder, pomegranate, onions, walnuts and other dyes.

Ikat is a fairly fashionable fabric among world-class couturiers; Gucci and Oscar De La Renta are sewn from it.

The USA, Milan, Paris, Rome applauded these fabrics, but unfortunately few people know anything about these fabrics, except that they are bright and oriental.

First of all, ikat is the name of the technology of applying dye to threads by hand before weaving the fabric.

The method of applying the dye is vaguely similar to the knotted batik technique.

And from these dyed threads the fabric is woven, always by hand, this is a feature of the technology.

The result is a slightly pulsating edge of the pattern, and there must be a white stripe – a slope.

The production process begins from afar – with the fattening of silkworm caterpillars.

This is how someone’s brand new silk dress grows on a tree :).

At the end of May, Uzbeks say “a new season of cocoons is ripening.” Young pupae wrap themselves in silk fibers into cocoons.

10 gr. caterpillars will grow to 80 kg cocoons. This will take 70 days. From 9 kg. 1 kg of containers comes out. silk threads, 12 kg of silk threads yield 250-300 m of adras or 100-150 m of shoyi.

The threads undergo 100 processes, or 120-150 days, to reach the final product.

The fabric production process begins simply – silkworm cocoons are processed.

Cocoons are boiled in hot water to soften the gluten.

This process is cruel; at the moment of processing the cocoons, the caterpillars are still in the cocoon, and when boiled down, they die.

If you wait until the silkworm itself comes out of the cocoon, the silkworm will gnaw through the cocoon and some of the threads will be damaged.

The treated threads are pulled onto a special frame on which the threads will be tied before dyeing.

The width of the frame is different for each master weaver; for the craftsmen with whom I collaborate, the width of the frame is 2.2 meters.

Threads are removed from the loom in bundles

And then they put it on a loom and weave it by hand.

The threads are pulled tightly into bundles, for example with tape, then everything is dipped in dye. In places where the screed is attached, the fabric remains white. If you need to dye the fabric in several colors, the fabric is pulled over the frame again, a new screed is applied, and dyed a second time.

It is here that the ikat fabric production process most closely matches the knotted batik technology.

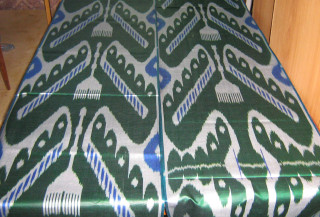

Ikat made by hand always has a white slope, along which the weaver aligns the ikat pattern. The ramp looks like this.

The frequency of repetition of the slope is equal to the width of the frame on which the fabric was stretched, that is, 2.2 meters.

If the fabric is made to order, you can make the repeatability of the slope 4.4 meters, that is, 2 * 2.2, but ikat fabric cannot be made without a slope at all.

Eastern tailors do not remove the slope, since ikat fabrics are woven, including from silk, and by hand, the fabric is expensive, and tailors are careful not to cut this fabric.

In addition, this white stripe confirms the handmade nature of the fabric, and helps to create things with a unique pattern.

Here is an example of fabric with a slope

It can be seen that the slope changes the pattern, destroys the symmetry, but also adds zest to the fabric.

Examples of oriental robes with a visible slope

Rear view of the robe. I took the photo from some museum. A ramp can be seen in the bottom center. And now the front view.

The slopes are also visible, and it is clear that the pattern was not selected symmetrically, or rather the pattern was not selected at all.

European designers try to sew symmetrical things, and this slope is cut out.

The thing becomes more symmetrical, orderly, and some of the chaos is removed.

But!! This technique increases the consumption of fabric for the product, and the cost of sewing the product corresponds.

Using the described technology, several types of fabric of different composition are made –

1)adras – fabric with cotton weft and silk warp,

2) shoyi – 100% silk fabric,

3) khan-atlas (it is made both manually and by machine)

4) alo-bakhmal – pile fabric.

A few ikat dyed with natural dyes – dyes: indigo – blue, onions – brown/yellow, and green was obtained by sequentially dyeing the fabric with indigo and onions (that is, yellow with green gave blue). – fabric is for sale (10 meters available).

dyes: blue – indigo,

red – madder dyeing – fabric for sale (10 meters available)

Dyes: yellow – onion, brown – walnut. fabric for sale (10 m in stock)